Brief Introduction: SoonSer Mars Pro 600 printed a 2656.84mm*900mm*3620mm relief wall. Clear and fine details that surpass the artwork of a professional sculptor.

The conventional method to produce a relief wall will exhaust a lot of raw material and manpower, not to mention the cost of production. Highly complex sculptures possess greater difficulties to produce in conventional method, however with 3D printing technology, all those problems can be solved easily.

3D Printed Relief Wall

Beautiful Details of Relief Wall

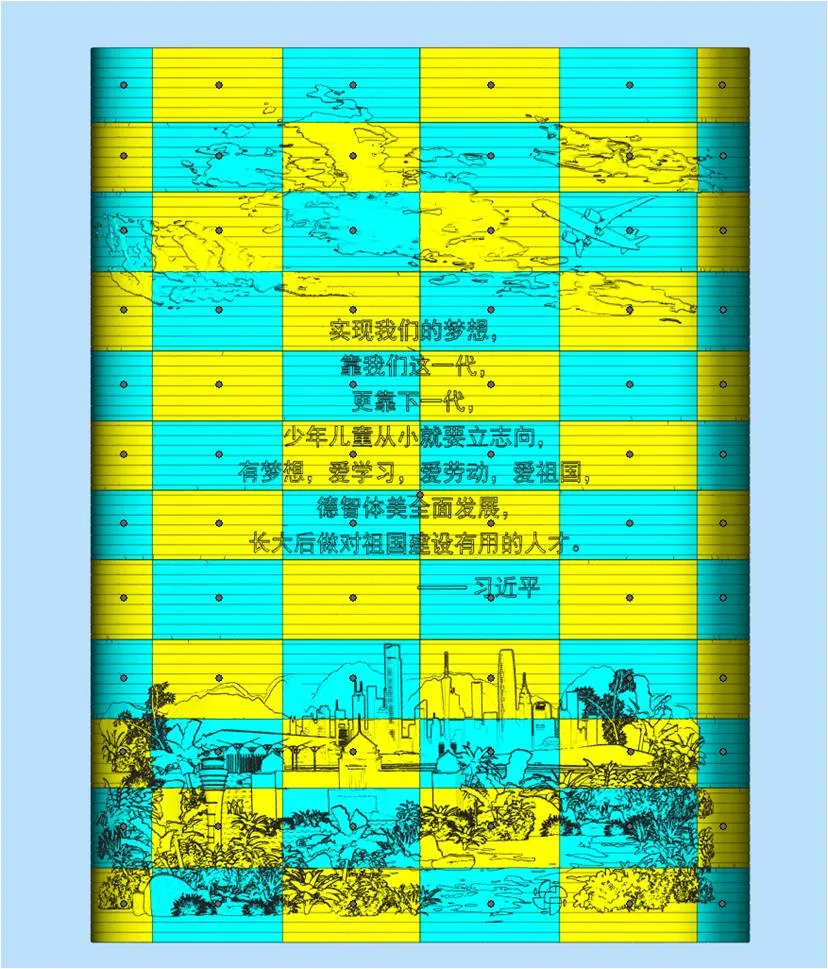

An experiment was conducted at an institute located in Guangzhou, China. The institute uses SoonSer 3D printer to fabricate a huge relief wall for indoor display. The wall is approximately 2656.84mm*900mm*3620mm with delicate lettering, patterns and curved lines. The finishing should consider aspects such as aesthetically pleasing, environmentally friendly, easy to clean and maintain.

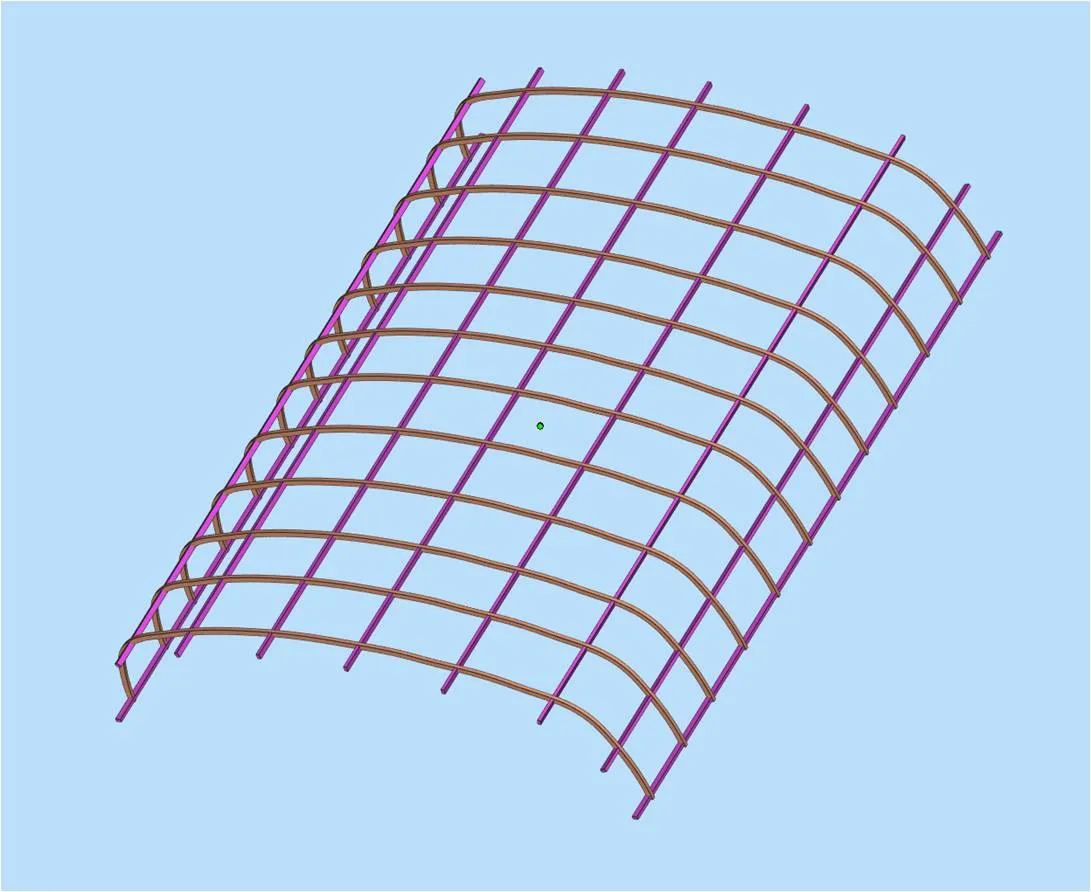

Upon primary evaluation, SoonSer 3D printer engineer developed a blueprint with the following specification, wall thickness of 2.5mm and a back-brushed FRP to ensure the structure is not deformed. This design ensure the print result to be natural and curved surfaces can be joined accurately after polishing.

Design Process at Software

The challenges of the project were that the curvatures of wall joints, complex patterns and different font's texture which would have been impossible to achieve using conventional method.With industrial grade 3D printer and resin material enable the project feasibility.

Design Process at Software

Fabrication procedure: The whole relief wall was printed with resin, with a wall thickness of 2.5mm, reinforcement made, wooden supports installed, and fiberglass applied. The whole wall was cut into 72 pieces and printed in 4 days.

Customers choose SLA 3D printing technology because SLA technique enables the following features:

● fast delivery: Files are given and products can be received as early as the next day.

● Good accuracy: Minimum printing layer’s thickness as low as 0.05mm, with a maximum forming accuracy of 0.03mm/100mm.

●Multiple surface effects: The final products are suitable for various surface treatment processes such as sandblasting, painting, dyeing and plating.

●Large size: the largest single forming size can reach 800*800*600 (mm); currently there is 1.6m equipment 1600*800*600 (mm) available.